Peek In Prosthodontics – An Overview

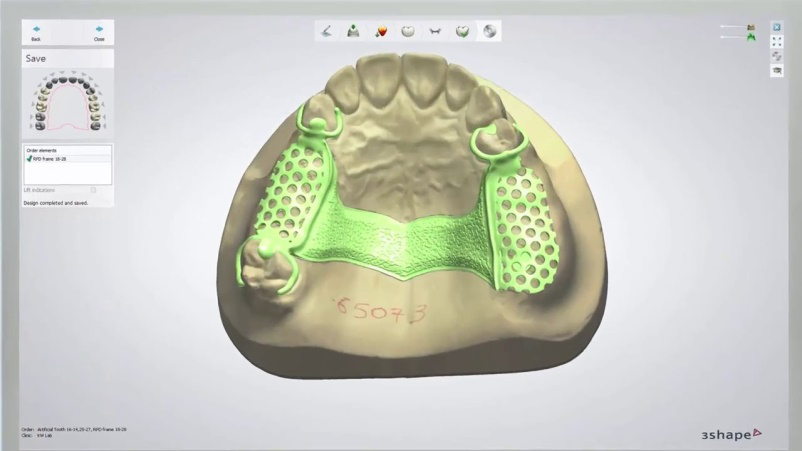

The advent of dental CAD-CAM technology (Computer-aided design & Computer-aided manufacturing) paved the way for increased machine-able materials appropriate for oral prostheses. One such material is PEEK (Polyetheretherketone) – a highly performed polymer that has been applied in dentistry with preferred physical, chemical, and mechanical properties.

A Small Introduction To PEEK

PEEK (Polyetheretherketone) is a half crystalline thermoplastic featuring excellent chemical-resistant and mechanical properties that retain at high temperatures even.

The peek material in prosthodontics has gained increased numbers of users and patrons owing to its toughness. It has proved to be a premium and innovative prosthetic solution in the world of dentistry – screw-retained, removable, or a permanent prosthesis.

Peek denture is a great alternative to metal and it can also be used for crowns as well as bridges.

Benefits You Can Enjoy With PEEK

The very first benefit patients can enjoy with peek in prosthodontics is it can be designed digitally and customized to match with the anatomy of the patient, unlike traditional methods. Further, the material is strong but lightweight adds much to your comfort. You won’t feel uncomfortable wearing them for a longer period.

Good for patients allergic to metals. Often we see people having metal allergies experience a burning sensation, irritation, and even redness. Thanks to the peek in dentistry which has NO metal flavor and patients can feel quite comfortable wearing them.

Its mechanical properties such as chemical-resistance, tissue-compatibility, thermal insulating, stability at high temperatures, etc. make PEEK a perfect choice for oral cavities.

Results have proven the purity of this material in dental implants worldwide. NO additives and NO coloring that can lead to body sensation.

Results Using The PEEK In Dentistry

In the field of dentistry, PEEK is a quite new material with excellent mechanical properties and has nice bonding with composite materials fulfilling basic needs to be applied in dental prostheses.

Video research found that CAD-CAM technology used in dental peek material resulted in lower deformation and is resistant to fractures. Additionally, the studies revealed that PEEK can be a viable substitute against other metals for dental prostheses and crowns.

Comparing PEEK with Zirconia, gold alloy, or lithium disilicate the former has shown higher modulus resilience. This indicates PEEK has a high elastic capacity to absorb harsh fracture energy.

Additionally, peek denture has proved to be low abrasive and high resistant to wear. It is a safe material that has shown performance for a longer period.

Related Products

Submitted successfully

We will contact you as soon as possible