Wet 5axis CAD CAM dental milling machine

The new CAD/CAM economic dental milling machine is cost-effective. It is an affordable option for dental laboratories that want to offer high-quality dental restoration services without breaking the bank. This is a significant advantage, especially for small-scale labs that are just starting out or those with a limited budget.

Advantages at a glance

1. High processing precision: zirconia milling machine adopts advanced numerical control technology, which can accurately process products of various complex shapes. The products produced are free from burrs, flaws and errors, and can accurately meet the needs of customers.

2. High processing efficiency: zirconia milling machine has fast processing capability and can process a large number of products in a short time. At the same time, the high degree of automation of the equipment reduces the need for manual intervention and improves work efficiency.

3. Wide applicability: The material of zirconia milling machine has wide applicability and can be used for processing various materials such as ceramics, titanium alloys, and resins. Whether it is a single product or mass production, it can meet customer requirements.

4. High safety performance: zirconia milling machine is a safe and reliable equipment. It uses high-quality parts and materials to ensure safe and reliable operation of the equipment, providing the necessary guarantee for customers' production.

· It conforms to the regular operation mode of desktop equipment in the industry.

· Understand the want at the back of each and every new feature and each and every new computer we create.

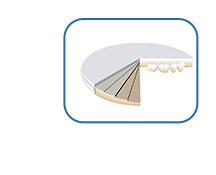

Cost- effective, high precision 5-axis simultaneous machining of small parts

Advantages at a glance

5- axis- GLS5T application case

Workbench Fixture

TP01 plate material fixture

Lithium Disilicate Fixture

TZ05 Titanium Column Fixture

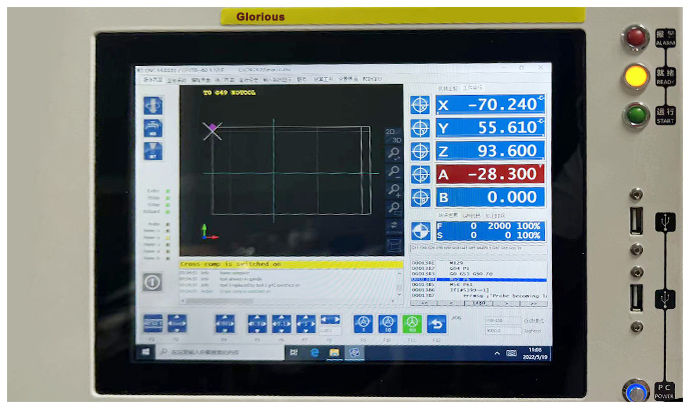

Control system

Workbench operation interface

Workbench operation buttons

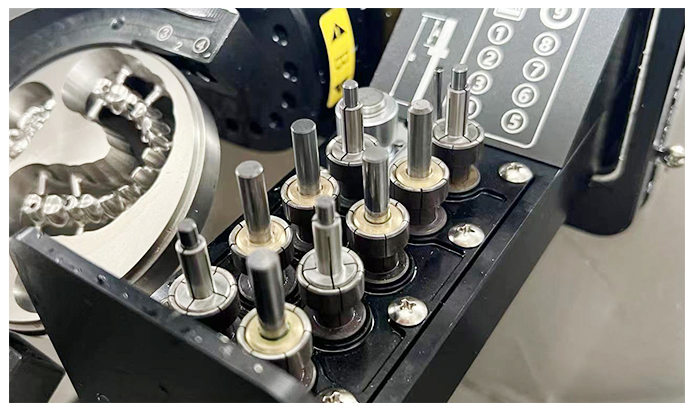

Automatic cutter change, cutter alignment

Cutter library

Strong structure

Overall, the GSL5T milling machine offers precise and efficient milling capabilities for small parts, with compatibility with various materials and a range of beneficial features that contribute to its high profitability.

If you have any further questions or need additional information, please feel free to ask. I'm here to assist you!

Related Products

Submitted successfully

We will contact you as soon as possible