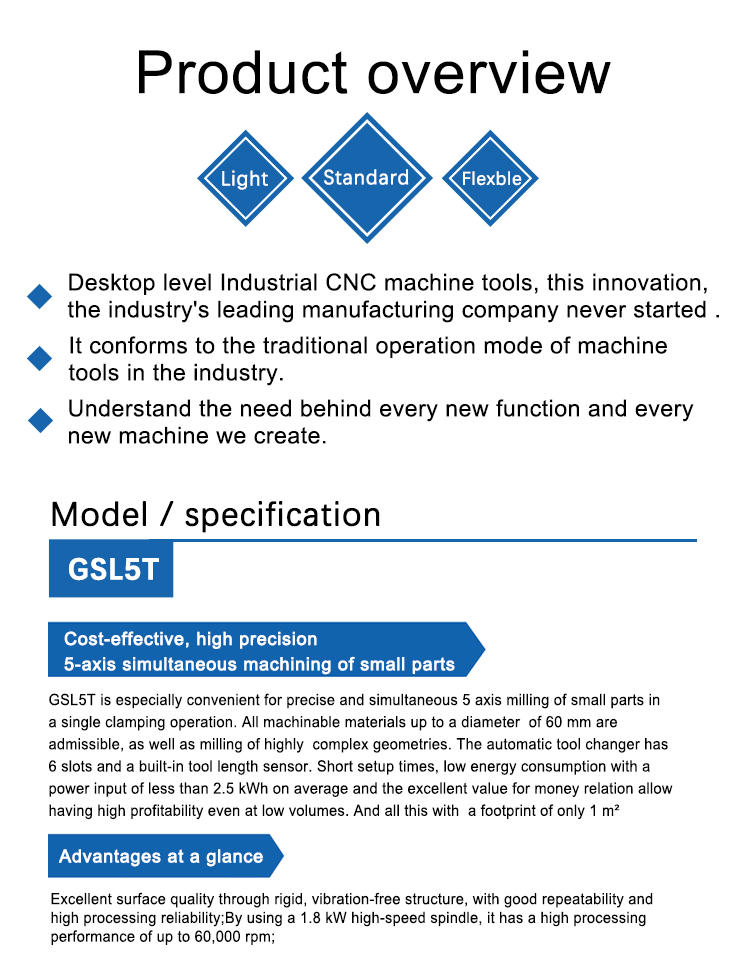

Dental Wet 5Axis Milling Machine

Cad cam 5 Axis Dental Milling Machine can improve work efficiency, reduce patient wait times, make it easier for dentists to perform occlusal tests, and reduce unnecessary second consultations. It is also possible to produce more accurate and comfortable dental restorations, such as temporary or permanent crowns, bridges, etc., to provide patients with a more technologically rich treatment experience.

Advantages at a glance

Excellent surface quality through rigid, vibration-free structure, with good repeatability and high processing reliability;By using a 1.8 kW high-speed spindle, it has a high processing performance of up to 60,000 rpm;

· It conforms to the regular operation mode of desktop equipment in the industry.

· Understand the want at the back of each and every new feature and each and every new computer we create.

Cost- effective, high precision 5-axis simultaneous machining of small parts

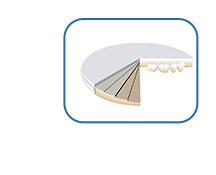

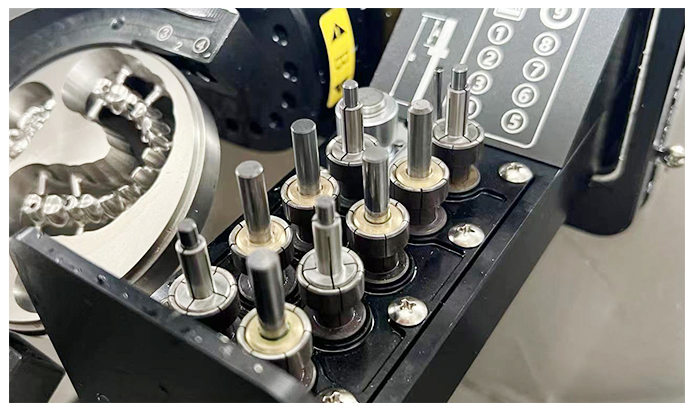

The GSL5T features an automatic tool changer with 6 slots, providing the ability to switch tools during the milling process easily. Additionally, it includes a built-in tool length sensor for precise tool positioning.

Advantages at a glance

Rigid, vibration-free structure: The GSL5T milling machine is designed with a rigid structure, providing excellent surface quality in the milled parts. The stability and lack of vibration contribute to better precision and smoother finishes.

Good repeatability and high processing reliability: The machine offers good repeatability, meaning that it can consistently reproduce the same results for multiple machining operations. This feature ensures consistent quality and reliability in the milling process.

High-speed spindle: The GSL5T is equipped with a 1.8 kW high-speed spindle, offering high processing performance. With a maximum spindle speed of up to 60,000 rpm, it enables rapid and efficient material removal, increasing productivity.

5- axis- GLS5T application case

Workbench Fixture

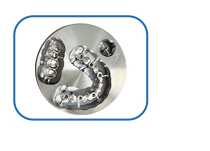

TP01 plate material fixture

Lithium Disilicate Fixture

TZ05 Titanium Column Fixture

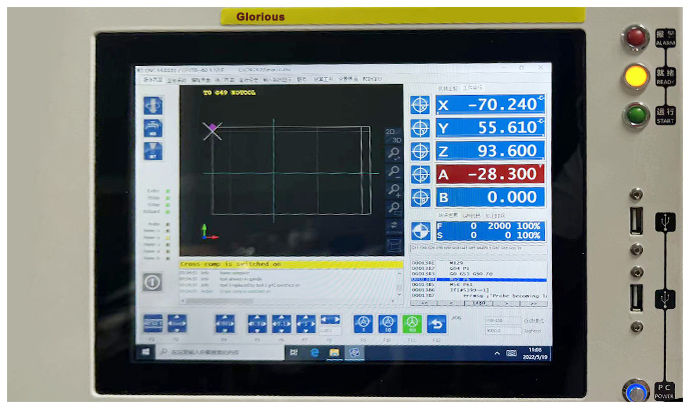

Control system

Workbench operation interface

Workbench operation buttons

Automatic cutter change, cutter alignment

Cutter library

Strong structure

These additional features contribute to the overall efficiency and performance of the GSL5T milling machine, allowing for precise, reliable, and fast machining with excellent surface quality.

If you have any further questions or need more information, please feel free to ask. I'm here to help!