Dental 5 Axis Digital CAD CAM Dental Milling Machine

5 axis special zirconia milling machine, special design of clamp, can hold half disk and milling, truly material saving. Like all-rounder in the sports ground, GSL5Z is the champi- on in dental field. Millable materials of GSL5Z covers almost all you can find in the market, product it mill can sat- isfy all your need. With hyperDENT CAM software and cut- ting-edge 5-axis technology,like a great warrior with even sharper weapon and harder shield

Cost- effective, high precision 5-axis simultaneous machining of small parts

Wide material compatibility: The machine can handle all machinable materials up to a diameter of 60 mm. This versatility enables the milling of various materials, including those with high hardness or complex geometries.

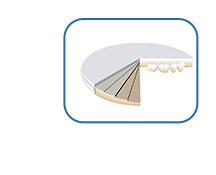

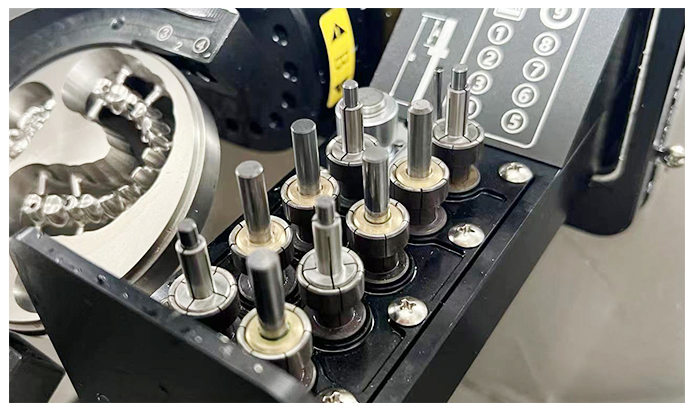

Automatic tool changer: The GSL5T features an automatic tool changer with 6 slots, providing the ability to switch tools during the milling process easily. Additionally, it includes a built-in tool length sensor for precise tool positioning.

Short setup times: The machine is designed to minimize setup times, allowing for more efficient production. This feature is particularly valuable when working with small parts and low volumes.

Energy-efficient: With a power input of less than 2.5 kWh on average, the GSL5T demonstrates low energy consumption. This helps to reduce operating costs and energy usage.

Excellent value for money: The combination of its features, efficiency, and reasonable price offers an excellent value for money ratio, making it a cost-effective solution.

Compact footprint: The GSL5T has a compact footprint of only 1 square meter, saving space in the production area.

· It conforms to the regular operation mode of desktop equipment in the industry.

· Understand the want at the back of each and every new feature and each and every new computer we create.

Cost- effective, high precision 5-axis simultaneous machining of small parts

Advantages at a glance

High-speed spindle: The GSL5T is equipped with a 1.8 kW high-speed spindle, offering high processing performance. With a maximum spindle speed of up to 60,000 rpm, it enables rapid and efficient material removal, increasing productivity.

These additional features contribute to the overall efficiency and performance of the GSL5T milling machine, allowing for precise, reliable, and fast machining with excellent surface quality.

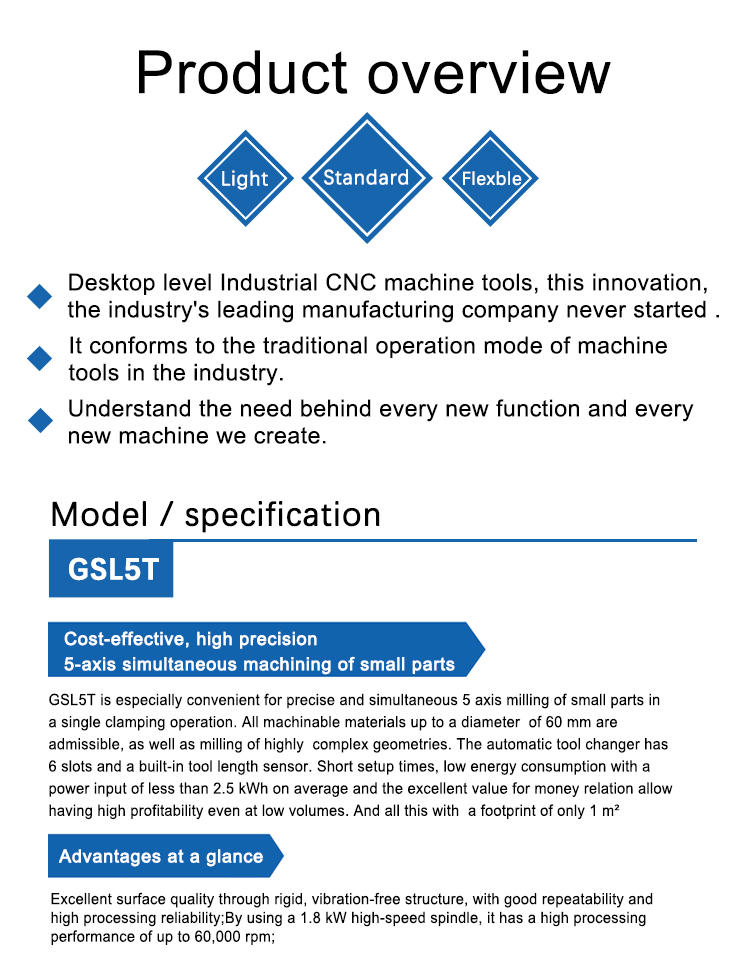

5- axis- GLS5T application case

Workbench Fixture

TP01 plate material fixture

Lithium Disilicate Fixture

TZ05 Titanium Column Fixture

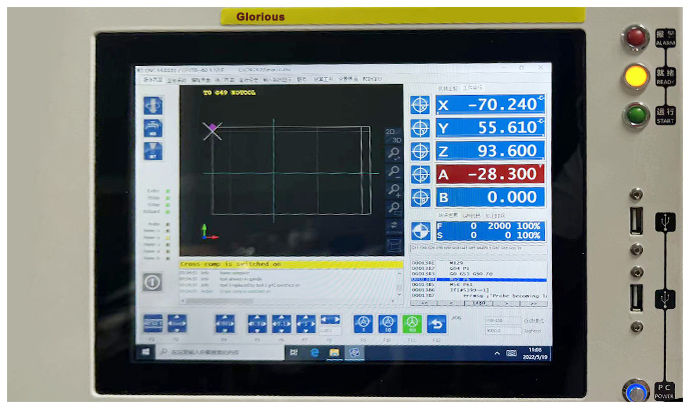

Control system

Workbench operation interface

Workbench operation buttons

Automatic cutter change, cutter alignment

Cutter library

Strong structure

If you have any further questions or need more information, please feel free to ask. I'm here to help!

Related Products

Submitted successfully

We will contact you as soon as possible