Dental ST Zirconia Block

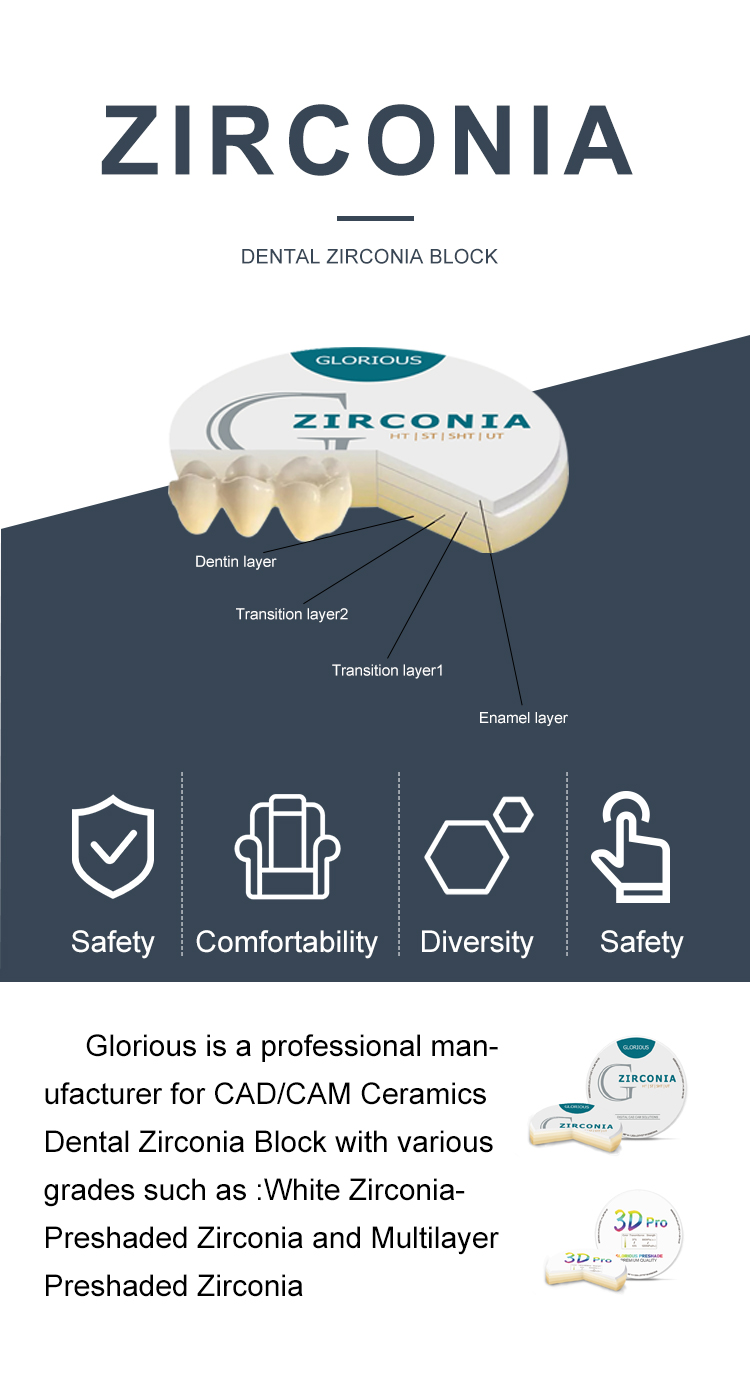

Zirconium material is an excellent high-tech biomaterial with good biocompatibility and superior to various metal alloys, including gold. Zirconium teeth have no irritation and no allergic reaction to the gums, so it is suitable for use in the oral cavity, avoiding allergic, irritation, corrosion and other adverse reactions caused by metals in the oral cavity.

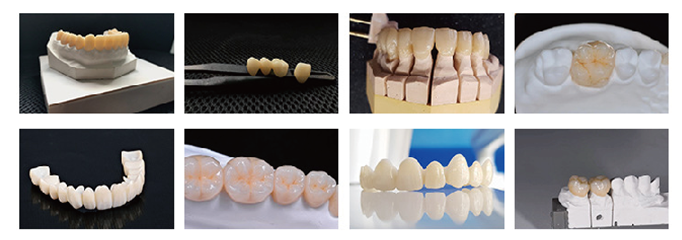

Product Intructions

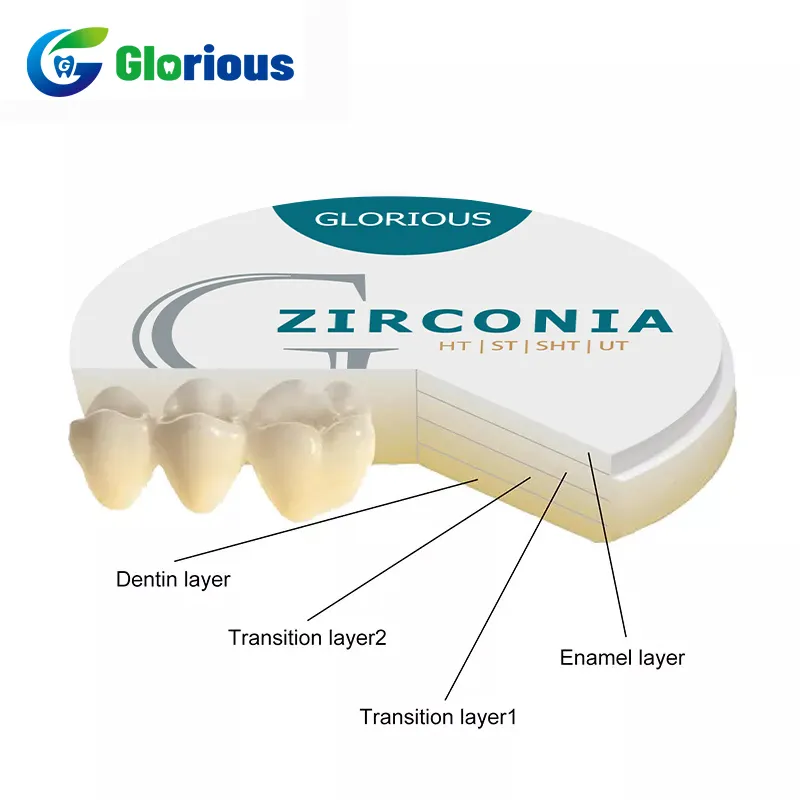

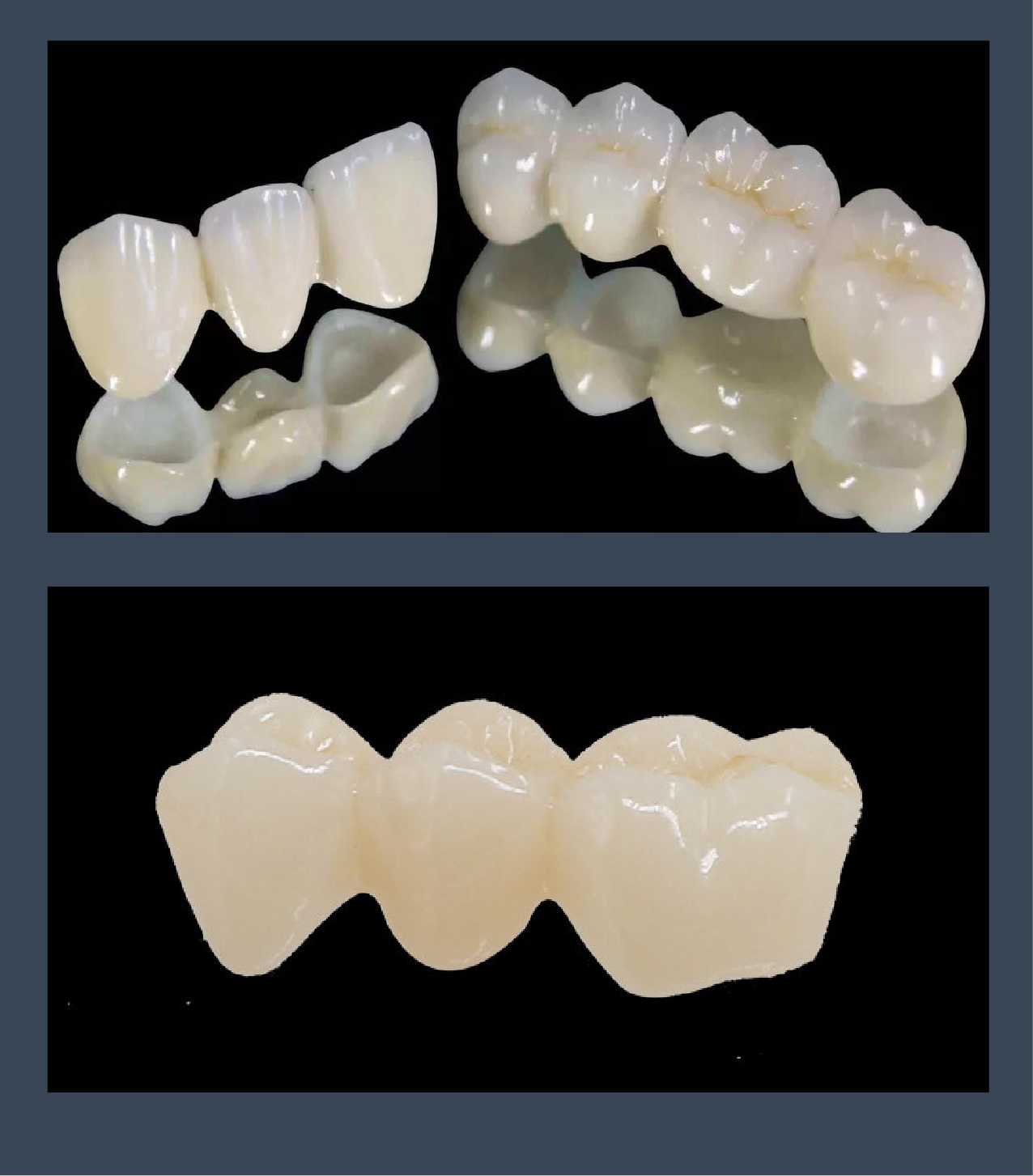

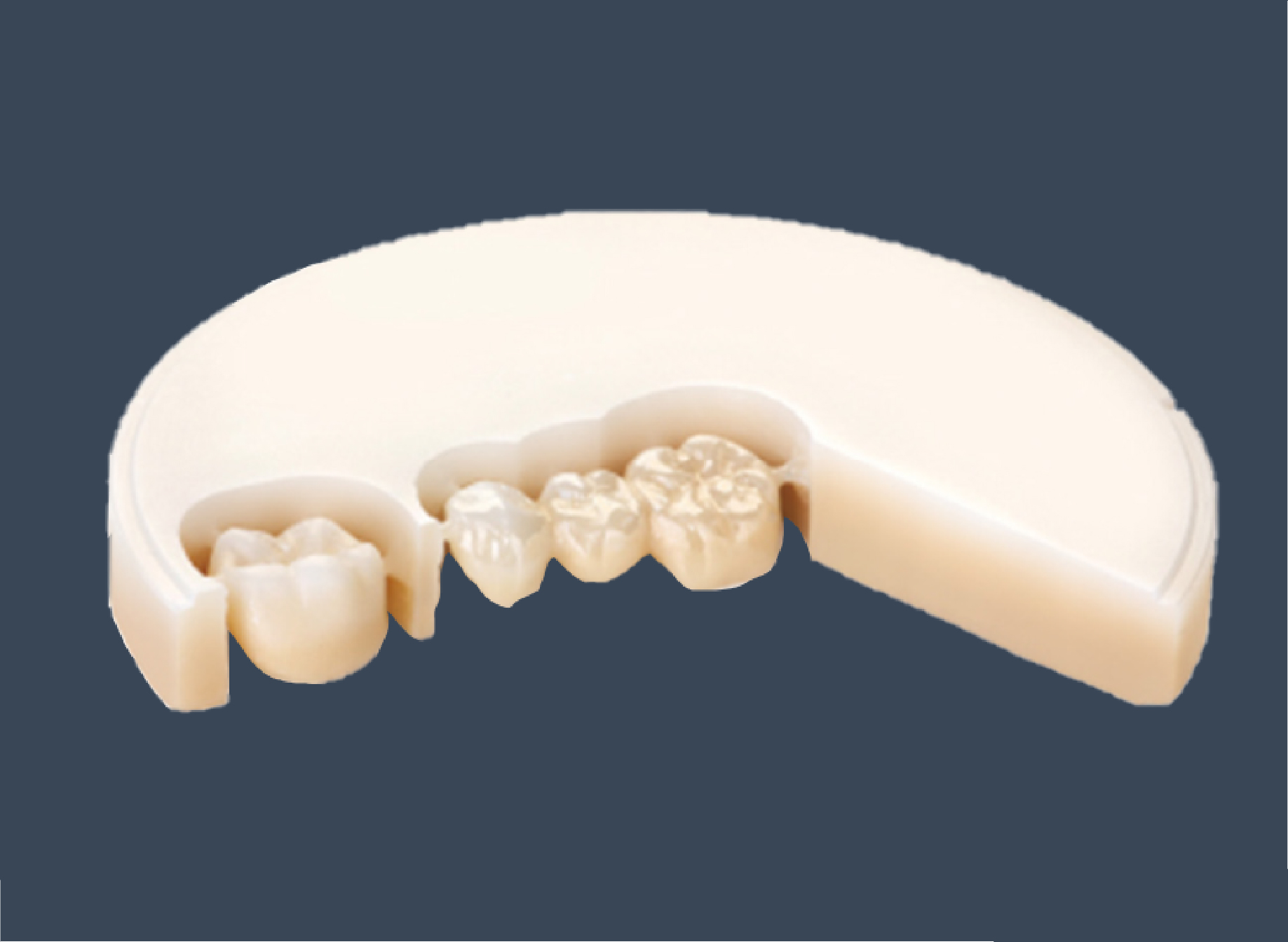

All-ceramic teeth are zirconia restorations that cover the entire crown surface and do not contain metal inner crowns. Because it is made of high-strength porcelain material close to the color of the teeth, it is more beautiful than metal-based porcelain restorations. The translucency is similar to natural teeth. After restoration, the gingival edge behaves more naturally, which can achieve the simulation effect and has a peripheral No tissue irritation, etc

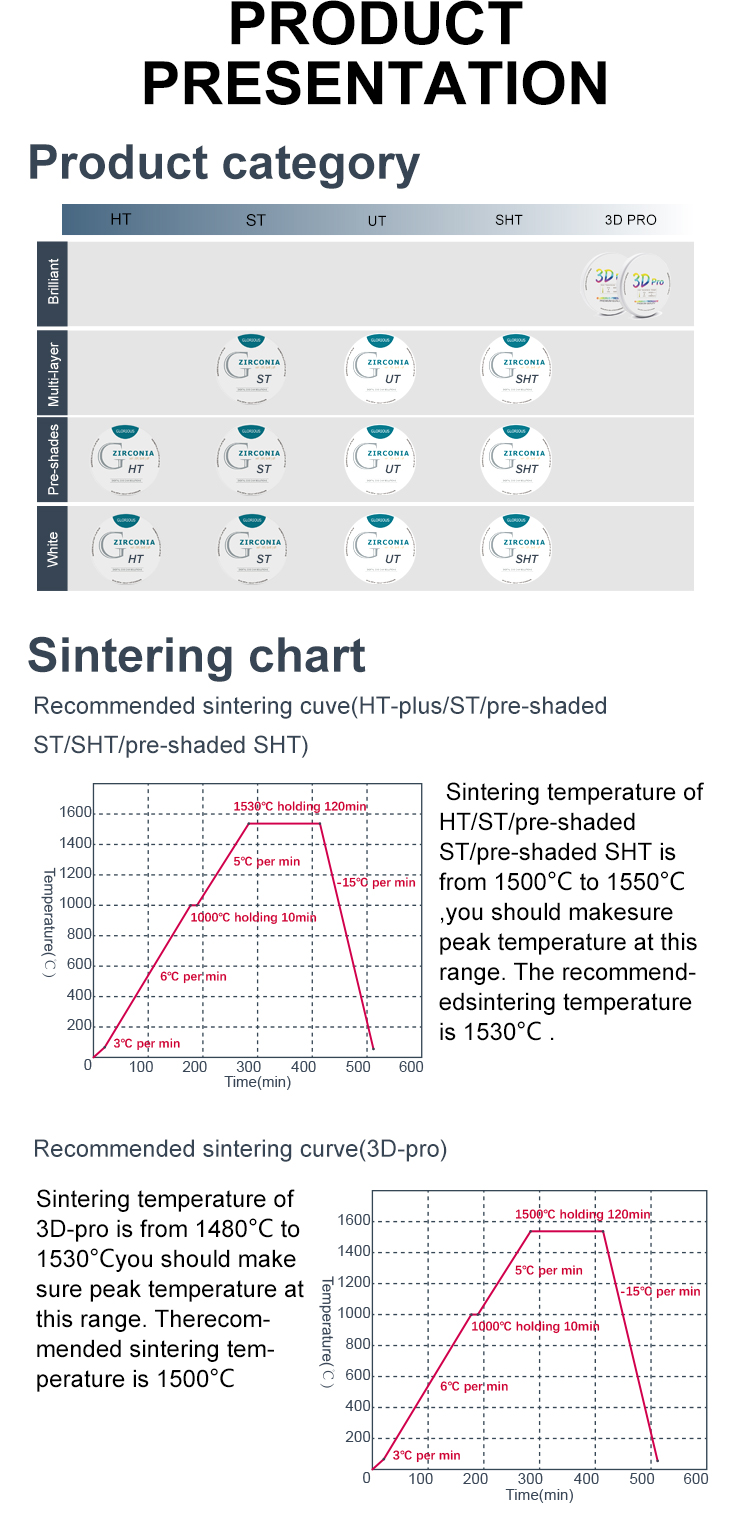

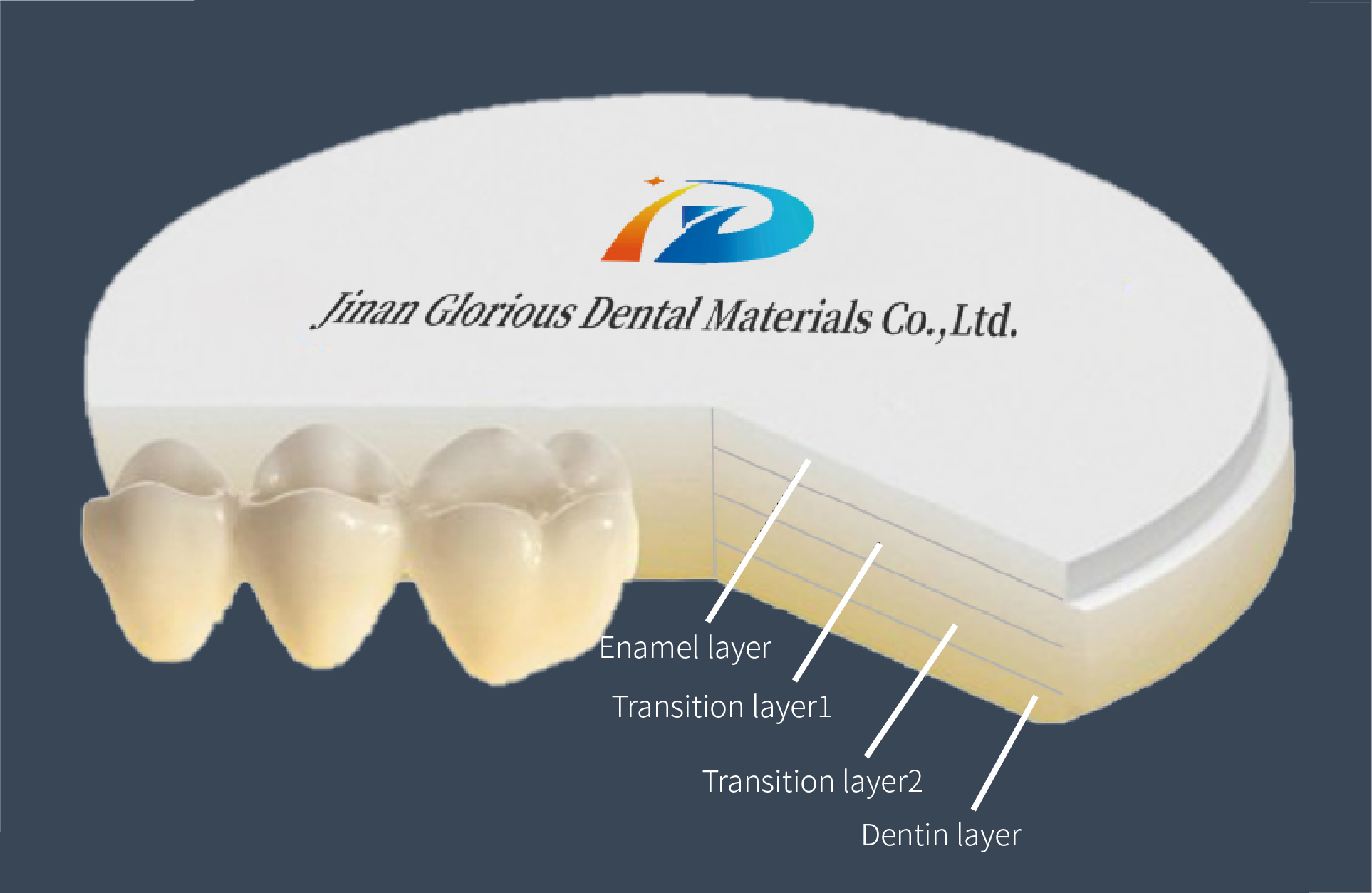

Glorious is a professional manufacturer for CAD/CAM Ceramics Dental Zirconia Block with various grades such as :White Zirconia Preshaded Zirconia and Multilayer Preshaded Zirconia

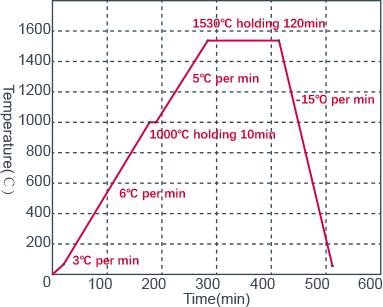

Sintering temperature of HT/ST/pre-shaded ST/pre-shaded SHT is from 1500°C to 1550°C ,you should makesure peak temperature at this range. The recommend- edsintering temperature is 1530℃ .

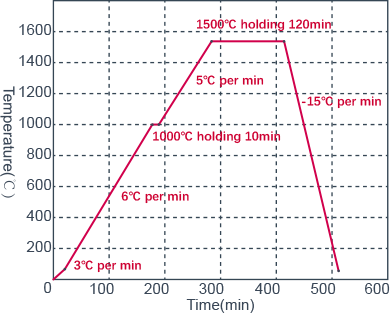

Recommended sintering curve(3D-pro)

Sintering temperature of 3D-pro is from 1480°C to 1530°Cyou should make sure peak temperature at this range. Therecom mended sintering temperature is 1500°C

Dental blanks

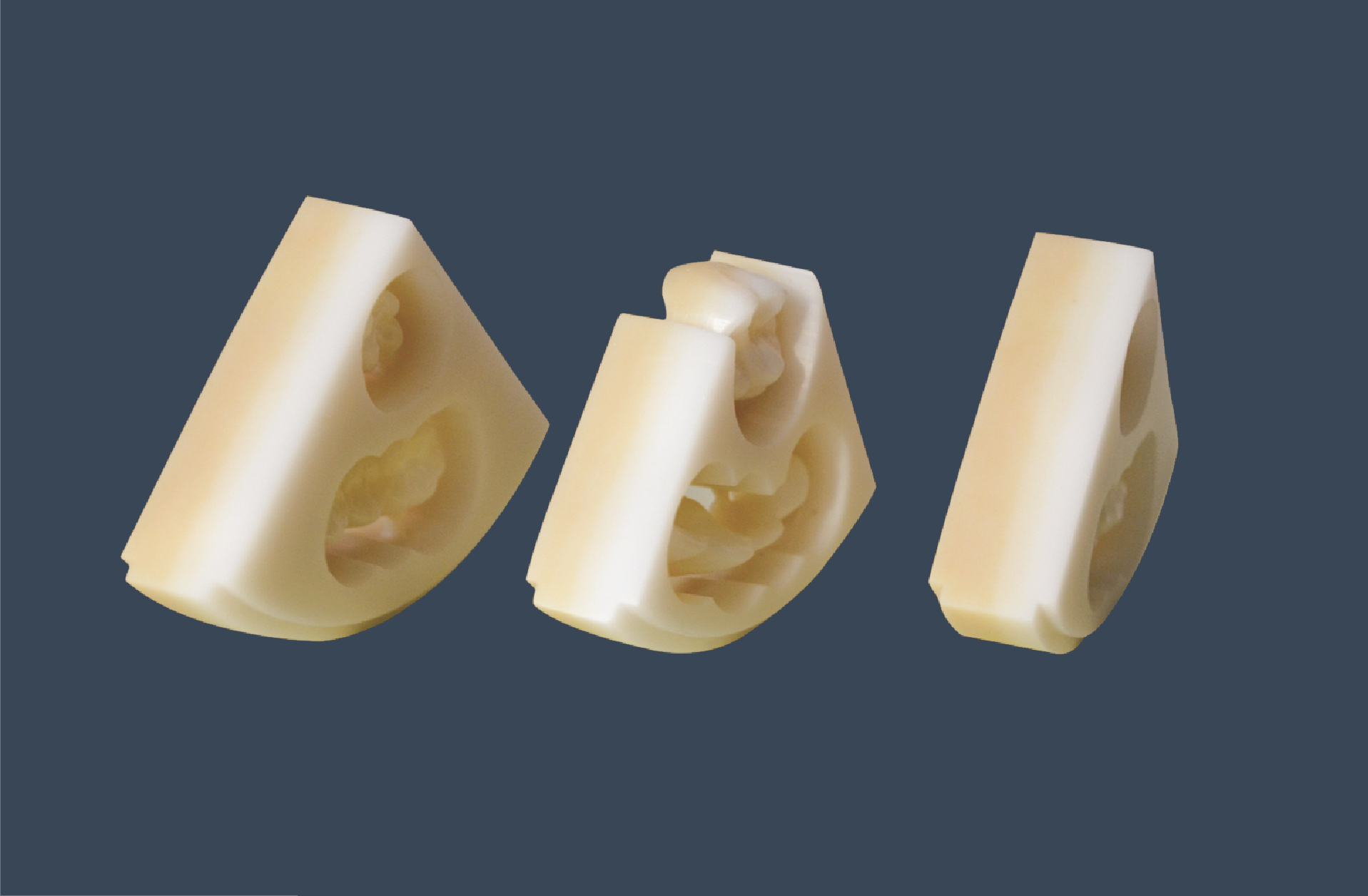

Zirconia powder

Zirconia block