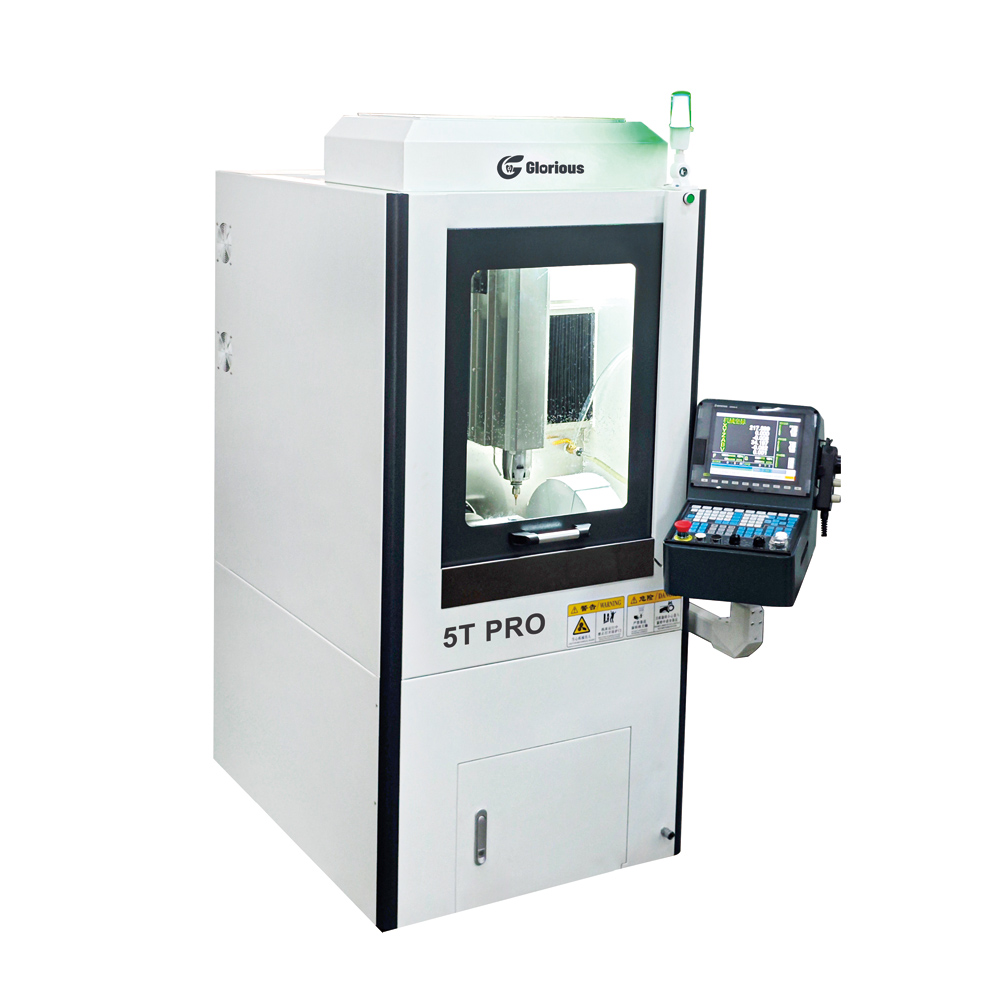

5T Pro Multifunctional Dental Milling Machine

The five-axis universal milling machine is equipped with a high-precision spindle and imported core components, and a flexible new-generation intelligent system, providing more accurate and reliable denture processing solutions for automated dentistry.

5T PRO

Multifunctional Composite Dental Milling Machine

Product Overview

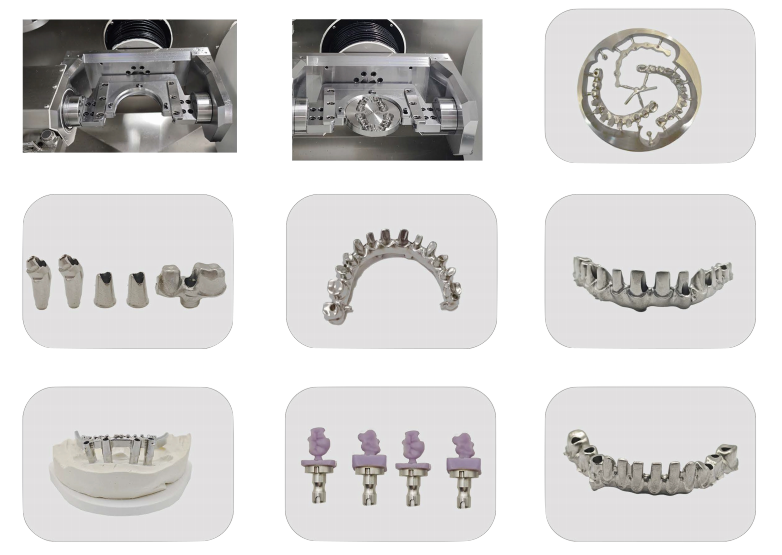

Support zirconia, wax, glass ceramic, preformed titanium post, pmma, peek and other dental materials;comprehensive functions, equipped with a variety of fixtures to choose from, a variety of machining processes easy to handle!

High-performance spindle:40,000rpm high speed true servo drive;4000w high power spindle, strong power, high efficiency cutting

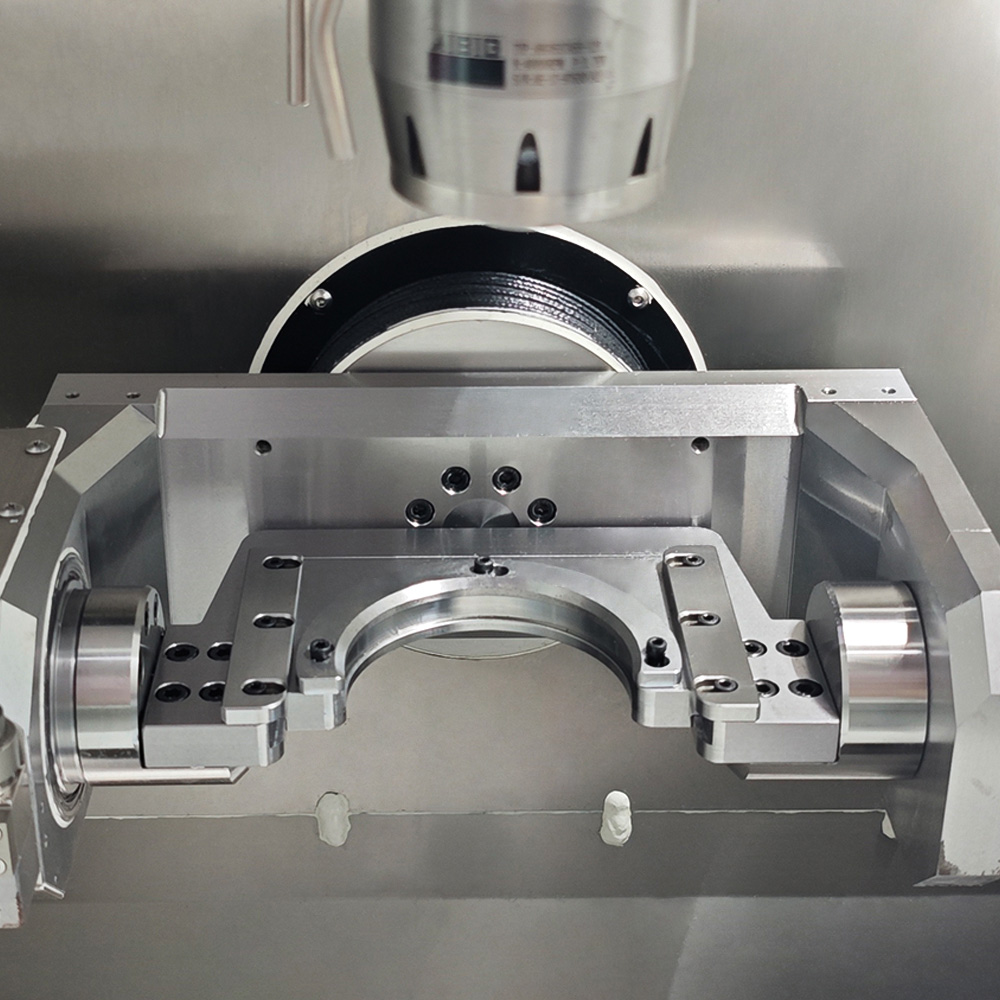

Derived from German CNC technology, 5-axis linkage, B-axis ±30°,A-axis 0°~360° ultra-large angle machining, higher contour precision.

Omni-directional warning system: Timely alarm in case of low air pressure, failed tool change, damaged tool setting instrument, etc., which protects the safety of your equipment and materials.

High-performance servo motor: Adopting full servo motor, millisecond startup, reliable performance and higher control precision.

Tool Life Cycle System: The system automatically calculates the life cycle of the tool, which is convenient for you to rationally plan the use and avoid losses due to wear and chipping.

The five-axis universal milling machine can perform micron-level precision cutting, operate stably for 24 hours, and has good rigidity. A wide range of material processing types can help you easily complete the processing of crown and bridge restorations,long bridges, bridge frames, brackets, bases and other high-precision restorations, and can also achieve complex operations such as stable opening of zirconium chloride crowns. The five-axis universal cutting machine is equipped with a high-precision spindle and imported core components, and a flexible new-generation intelligent system,providing more accurate and reliable denture processing solutions for automated dentistry.

The main technical parameters

| Spindle speed:3.7KW/40000rpm | Servo motor power:400W/200W |

| Tool holder specification:ISO20 | Chuck specification :ER16 |

| Tool clamping range:Φ1-10 | Repeatability accuracy:±0.003mm |

XYZ axis running reciprocating accuracy):+0.01/300mm | Working flatness:±0.005mm |

| Weight:About 1.3 tons | Power configuration:three-phase four-wire 380V/50HZ |

Product parameters

Corresponding model 5T PRO | ||

Four Five axis configuration | German original reducer | One arcmin accuracy±40degrees(disc Five axes:rated torque 88.9N.m instantaneous maximum torque 312N.m rated speed 43 rpm Maximum speed 85) Four-axis:rated torque 44.6N.m, instantaneous maximum torque 156N.m, rated speed 43 rpm,maximum speed 85 |

Transmission components | German original precision guide rail and screw rod | Repeatability accuracy:±0.003mm |

| System | Taiwan SYNTEC System | 220MA-10.4 inch split milling machine controller |

| Servo drive | Branded motors and drives | 400W |

| Precision spindle | Good Brand electric spindle | 3.7kw electric spindle,Maximum speed 40000 rpm |

| Automatic tool set-up | Precision tool setter | Repeatability 0.002mm |

| Oiling | Oil injection pump lubrication system | Timing automatic oiling(grease) |

| Cooling spindle | Brand water cooler | Coolant circulating cooling flow alarm |

| Fast tool magazine | Brand servo motor | 15 knives can be replaced |

Main configuration

German fifth axis: German Alpha ALPHA high-precision fifth axis linkage structure

German fourth axis: German Alpha ALPHA fourth axis precision linkage structure

German screw guide: German Rexroth REXROTH ball screw guide, with adjustable nuts

Taiwan New Generation System: Taiwan New Generation Full Chinese control system

Japanese servo drive: Japanese Yaskawa oil-proof series high-resolution servo motor, with better linkage effect

Precision spindle: CNC dedicated high-speed high-precision automatic tool change spindle

Automatic tool setting: fully automatic tool setting instrument, effectively compensates for tool length

Automatic lubrication: Automatically lubricates the machine tool guide rails when ready to run, effectively extending the service life of the guide rails

Spindle water cooling: The spindle temperature can be set, the spindle is not easy to heat up during continuous processing, and the service life of the spindle is extended

Oil mist recovery: effectively recover and filter the oil mist generated during continuous processing, purifying the processing environment

Core accessoriesz

Glorious Dental Materials Co., Ltd. is a high-tech enterprise integrating R&D, production and sales of CNC systems andCNC machine tools, providing high-quality, high-stability and high-precision processing equipment for denture processing. We always adhere to the business philosophy of "application first, quality first", and take "professional, dedicated and focused" as the core development path. Through unremitting efforts, we have created a professional team with vitality and enterprising spirit. The company is committed to high-quality denture processing, quickly responding to customers' changing needs, and providing industry customers with advanced, reliable and high-quality denture milling machine and solutions.If you have any dental products you are interested in, please feel free to contact us.

Related Products

Submitted successfully

We will contact you as soon as possible