7. Adhesive, self-adhesive and conventional cementation options, despending on the restoration type 8. Every time without glaze,the unique color change effect to ensure perfect repair effect

Dental Glass Ceramics Lithium Disilicate

The lithium disilicate in dentistry system has attracted great attention since the development of the first glass-ceramic based on the stoichiometric composition of lithium disilicate. Dental Lithium disilicate is a new form and better way of technology that erases the idea of tooth plucking and introduces a new way of filling the tooth with unique yet special material. The idea of this material is to replace your old tooth with a new one, yet both are serving the same purpose and they take the same tooth structure. The material that is used for dental lithium is a glass-ceramic that includes lithium and silicon.

Products Description

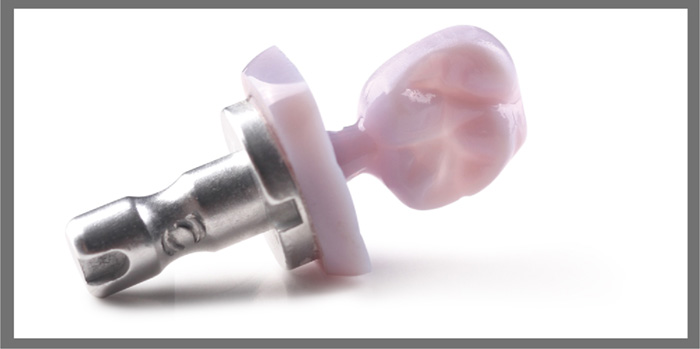

Lithium Disilicate in dentistry application is now available in every dental care facility as it’s made in the laboratories or chairside using the CAD/CAM technology. It is most preferred as it demonstrates a strength of 360 MPa and has a flexible nature of restoration by either adhesively bonded or conventionally cemented can be fabricated either in the laboratory or chairside using CAD/CAM Sirona Cerec MCXL Burs milling technology.

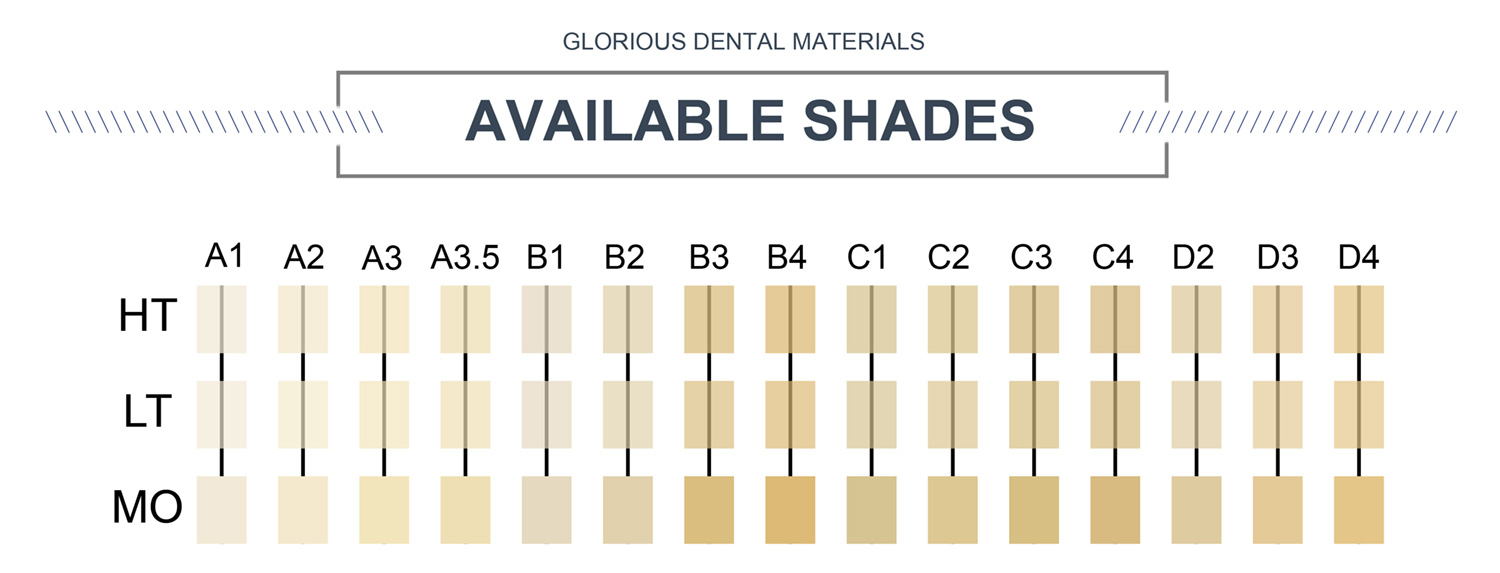

E.max CAD HT (High Translucency):

Ideal for fabricating small restorations such as inlays and onlays.

Offers high translucency, similar to natural enamel, for a natural esthetic appearance.

Provides a true-to-nature chameleon effect and exceptional adaptation to the remaining tooth structure.

Especially useful for minimally invasive procedures.

E.max CAD LT (Low Translucency):

Suitable for fabricating larger restorations, particularly posterior crowns.

Demonstrates low translucency, similar to natural dentin, enhancing lifelike brightness and chroma of the restoration.

Prevents the incorporated restorations from appearing grey, maintaining a natural appearance.

E.max CAD MO (Medium Opacity):

Designed with a higher opacity, making them suitable for fabricating frameworks on slightly discolored preparations.

Primarily used in dental laboratories for fabricating the underlying structure of the restoration.

These different types of E.max CAD blocks offer versatility in terms of translucency and opacity, allowing for customized restorations based on the specific clinical needs and desired esthetics of the patient.

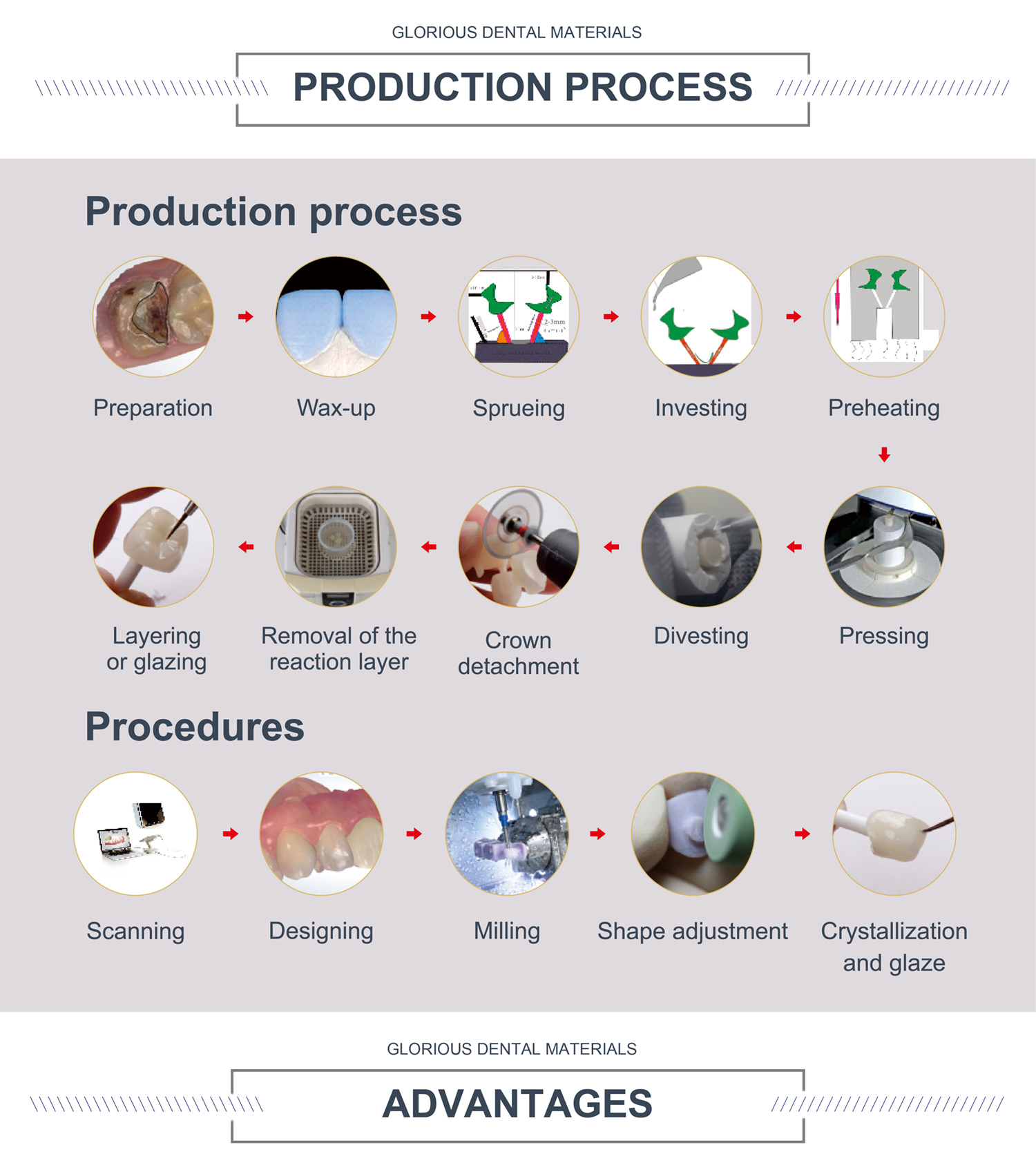

1. Excellent esthetics and high strength of 530 MPa2, efficiently obtained in the dental practice

3. High aesthetic repair effect

4. High chemical stability and binging strength

5. Easy milling,prolong the service life of burs

6. Simple and rapid crystallization process to reduce operating time

Two - step process

These different types of E.max CAD blocks offer versatility in terms of translucency and opacity, allowing for customized restorations based on the specific clinical needs and desired esthetics of the patient.

If you have any further questions or need additional information, please feel free to ask. I'm here to help!

Related Products

Submitted successfully

We will contact you as soon as possible