1. Excellent esthetics and high strength of 530 MPa2, efficiently obtained in the dental practice

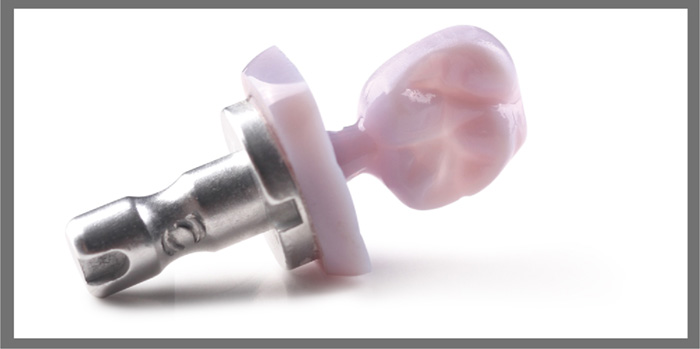

Dental B40 Glass Ceramic Lithium Disilicate

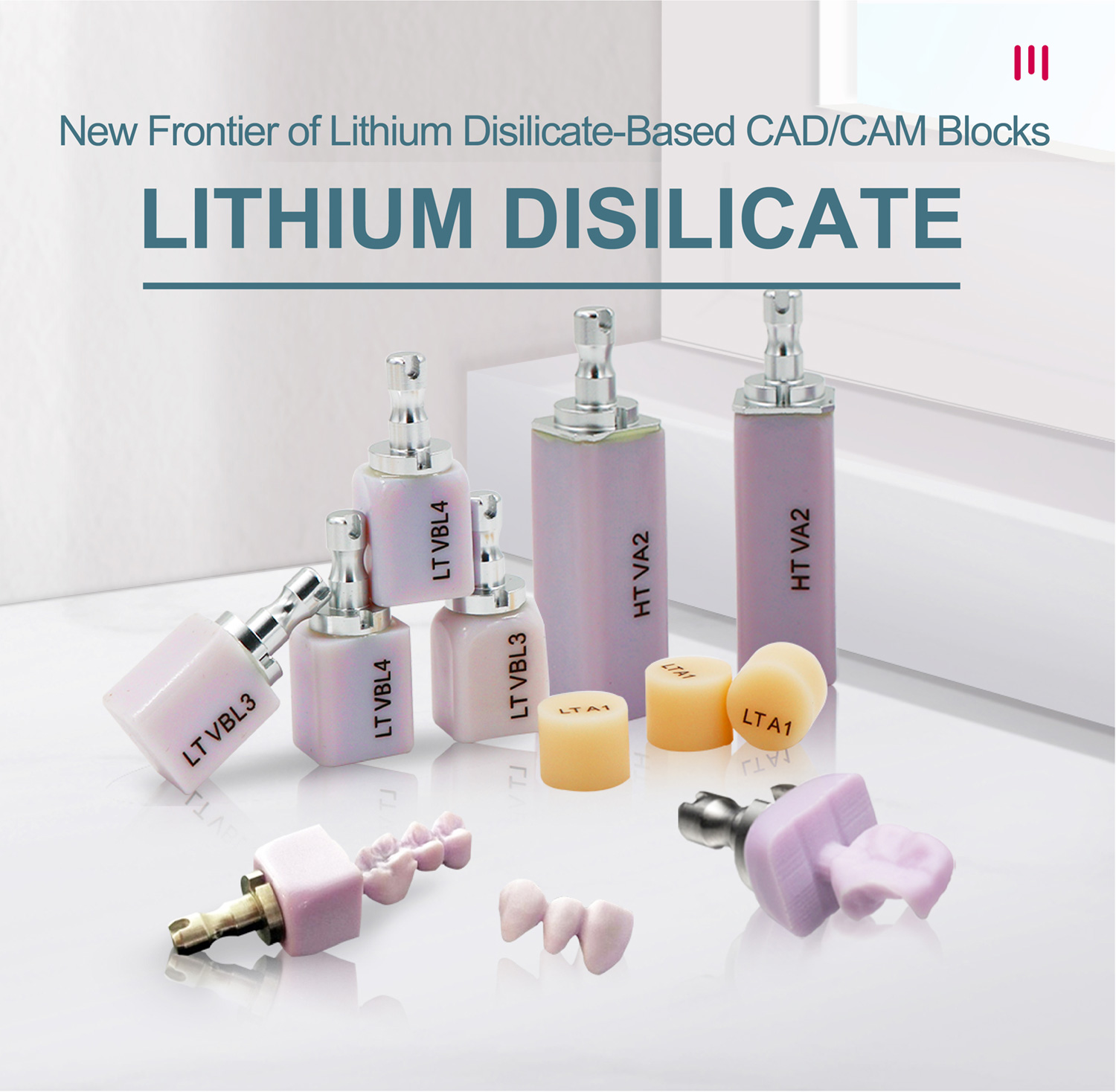

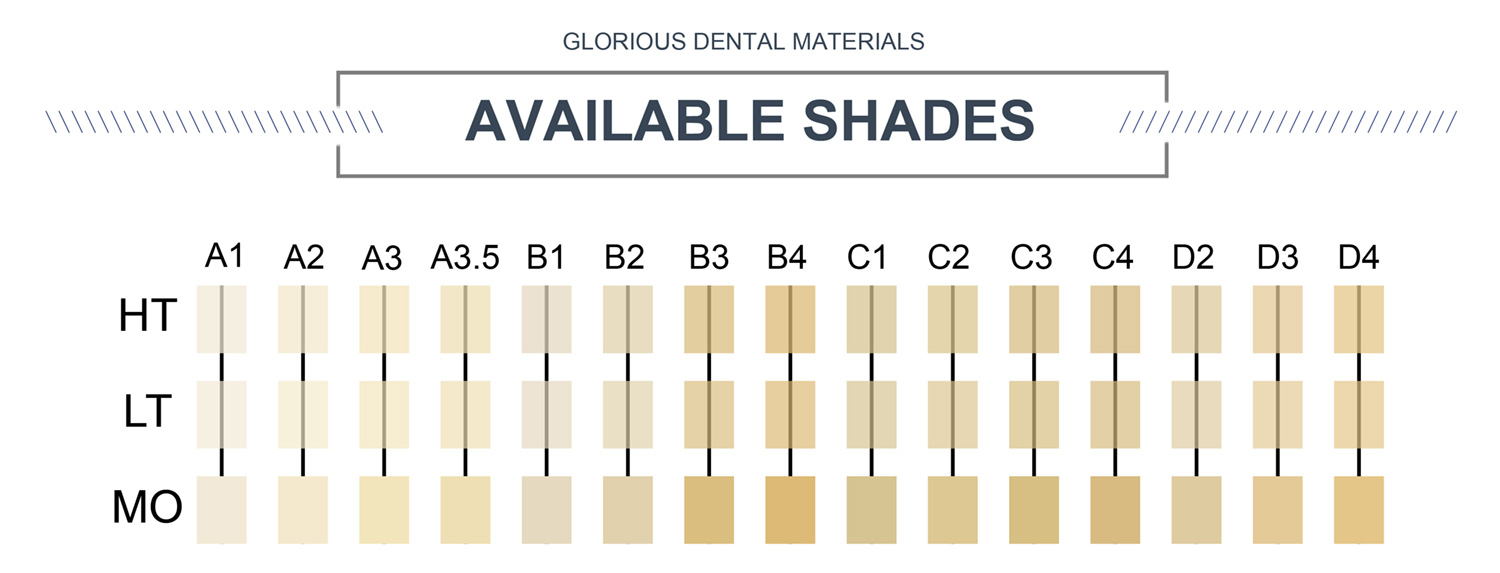

Lithium disilicate is a strong, all-ceramic material available in ingots for pressing (IPS e.max Press) and in blocks that can be milled with several different CAD/CAM milling machines (IPS e.max CAD). It’s available in many shades, both chromatic (dentin) and bleach, and has a wide variety of uses including limited-size bridges, anterior and posterior full contour crowns, inlays and onlays, veneers, minimal prep veneers, telescopic crowns for masking dark preparations and adding dentine when inadequate, and telescopic bridges for supporting veneers within smile design.

Products Description

As all-ceramic materials become stronger, the need for both metal and zirconium frameworks will diminish and we’ll see the demise of some outdated and costly fabrication techniques. For instance, the use of frameworks for single-unit restorations is all but obsolete in my opinion, thanks in large part to the fact that lithium disilicate restorations can be adhesively bonded or cemented in the traditional way. Fabricating fully anatomical restorations without frameworks is the future of dental technology.

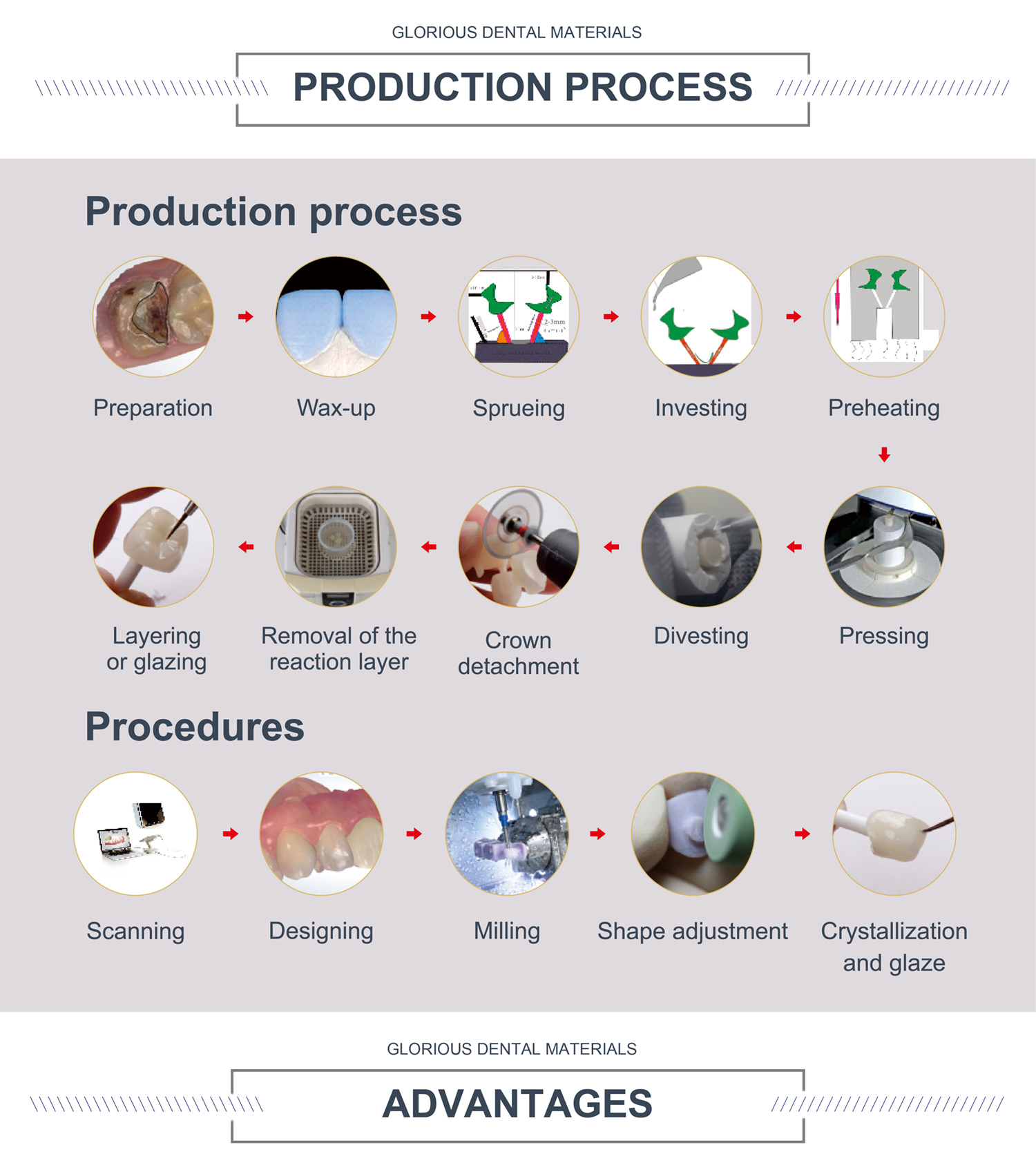

1. Excellent esthetics and high strength of 530 MPa2, efficiently obtained in the dental practice

3. High aesthetic repair effect

5. Easy milling,prolong the service life of burs

glaze,the unique color change effect to ensure perfect repair effect

Two - step process

These restorations can be stained and glazed and/or cut back, require less ceramic layering and can be fabricated both digitally and with lost wax techniques. The result is a more esthetic restoration that’s easier to replicate consistently with less expense and less labor. Another distinct advantage is the elimination of using dissimilar materials which often have completely different thermal characteristics that can impact the quality of the restoration.

If you have any questions about glass ceramics, you can contact me!

Related Products

Submitted successfully

We will contact you as soon as possible