Glorious Dental Porcelain Furnace

New Product Advantage:

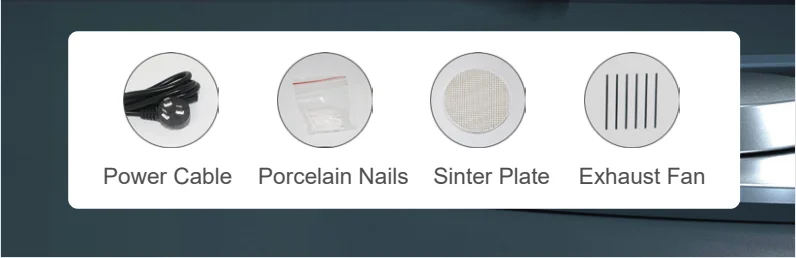

Product Intructions

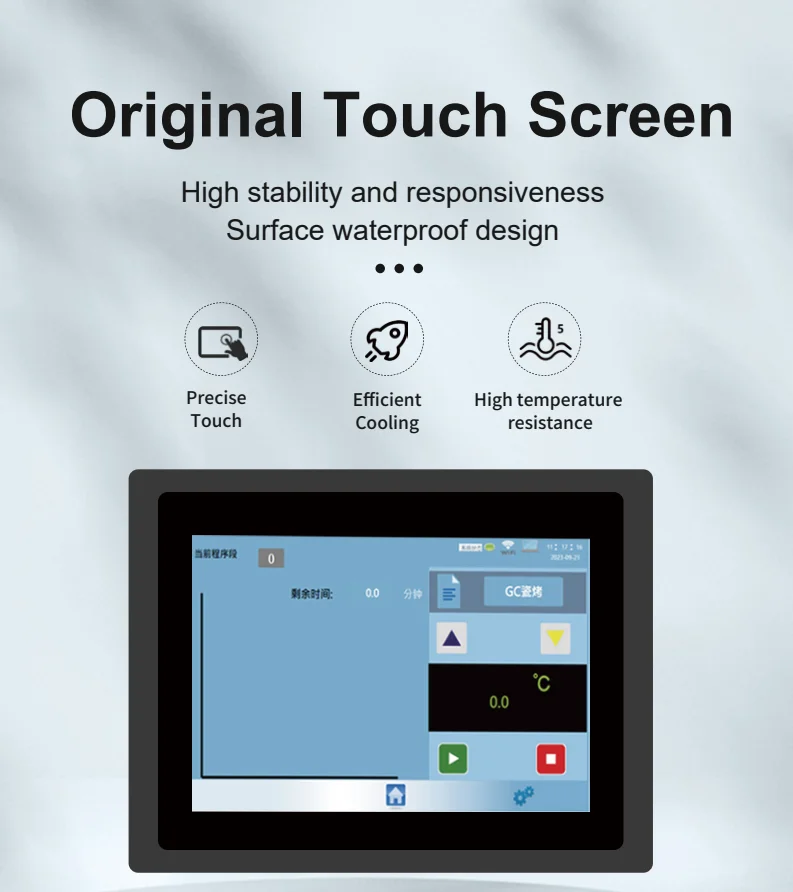

The new furnace's high-quality automatic temperature regulation within ±1°C is a valuable feature for precise temperature control. This ensures accuracy and consistency in denture processing, resulting in high-quality results.The built-in automatic cooling program eliminates the manual cooling process and makes the use of the vacuum cleaner more convenient. This saves time and effort and makes the workflow in industrial denture processing plants more efficient.

The remote programming function through mobile phones, tablets, web pages, etc. provides users with flexibility and convenience. This allows easy uploading and downloading of programming instructions, firmware upgrades, diagnostics and monitoring. In addition, on-site anomaly detection ensures that any issues that may arise during operations are promptly identified and resolved.

The annular distribution of heating elements within the furnace is a distinctive design feature. This ensures a more even furnace temperature, especially at high temperatures. This uniform temperature distribution helps maintain consistency in denture processing and improves the overall quality of industrial denture production.

These advanced features help improve the efficiency, accuracy and quality of denture processing in the factory. Automatic temperature regulation, remote programming capabilities and even temperature distribution combine to achieve a streamlined process and superior results.

If you want to know more information about dental porcelain furnaces, please contact me

Related Products

Submitted successfully

We will contact you as soon as possible